A multi-disciplinary scientific collaboration from the government, academia, and business has joined forces to find innovative ways to lessen the environmental effect of polyurethane, one of the most frequently used yet seldom recycled plastic materials.

Polyurethane Usage

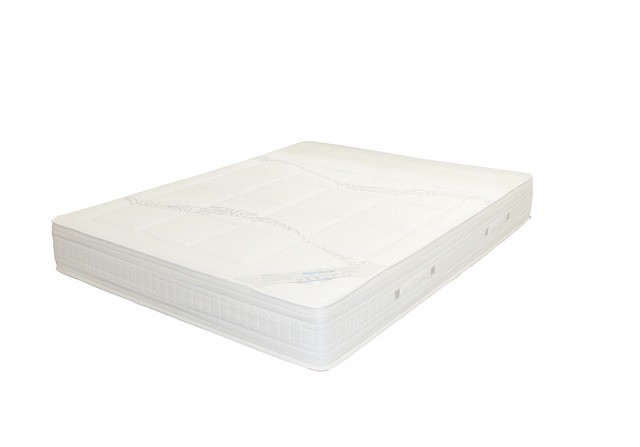

Although polyurethane is one of the most extensively used plastic compounds on the planet, it is sometimes disregarded in our everyday lives. Whether you're at home, at work, or in your car, it's generally not far away, with frequent end applications ranging from mattresses and furniture cushioning to building insulation, automobile components, and even shoe soles.

However, along with other plastics that are generally unrecycled, polyurethane's ubiquitous use raises environmental concerns. Researchers from the United States wanted to learn more about the possibilities for recycling polyurethane and replacing the chemicals used in its manufacturing with plant-based alternatives. The first complete evaluation of "Material Flows of Polyurethane in the United States" was recently published in the journal Environmental Science & Technology by the Department of Energy's (DOE) Argonne National Laboratory, Northwestern University, and The Dow Chemical Company.

"The goal was to understand how linear versus how circular our use of polyurethanes in the United States is," said Jennifer Dunn, associate director of Northwestern's Center for Engineering Sustainability and Resilience and a member of the Institute for Sustainability and Energy's Program on Plastics, Ecosystems, and Public Health (ISEN). "We also wanted to explore whether there were any changes to improve polyurethane circularity and bio-based content."

How Plastics Plays a Role in the System

A linear economy is when raw materials are employed to manufacture goods and then discarded at the end of their useful life. Those same resources are collected and reused in a circular economy. This reduces the quantity of garbage delivered to landfills while limiting the need to extract more natural resources, such as fossil fuels.

While researchers expected to find an essentially linear system for polyurethanes, Dunn, who is also an associate professor of chemical and biological engineering at Northwestern's McCormick School of Engineering, said that "looking at it from a materials flow perspective, from the starting materials to the end of life, it was just blatantly linear."

The analysis revealed a variety of variables that impact how and when polyurethanes may be recovered and recycled, according to co-author Troy Hawkins. He directs the Fuels and Products Group in Argonne's Systems Assessment Center.

"Polyurethanes come in a variety of forms, from rigid to flexible, and each of these applications looks and acts differently. The use of polyurethanes has increased in the last 50 years, and many benefits are long-lived, so what's in service now may not be out of use for another 10, 20, or 30 years. There's also a problem with the concentration of polyurethane in various applications. For example, an adhesive or sealant is much harder to separate and recover than

Diisocyanate

Furthermore, hazardous compounds called diisocyanates have long been employed in polyurethane supply chains, and the study established how and where they are used.

"Having this whole picture helps us to recognize prospects for recovering and recycling polyurethane, as well as replacing some of the inputs to polyurethane manufacturing that have environmental and safety problems with safer, low-carbon bio-based chemicals for the first time," Hawkins added.

A Large Collaboration

The study's inclusion of Dow was one of its distinguishing features, according to Dunn, because it allowed the researchers to add precise data and technical knowledge based on genuine business procedures.

"Dow was critical to this work since the Dow co-authors' experience anchored the analysis in real-world understanding of how polyurethanes are created and utilized," she explained. "They're also keen on improving the circularity of their systems and staying ahead of the curve when it comes to adding greener materials."

Hawkins said there was also a strong partnership between Argonne and Northwestern, with each providing a diverse set of expertise and resources accumulated through time. "It provided synergies and opportunities that we would not have had otherwise," he added. "It also allowed us to include additional components that we don't normally track in life cycle evaluations," says the author.

It took around a year to finish the job. It was part of the joint three-year Responsible Innovation for Highly Recyclable Plastics effort, supported by the DOE Bioenergy Technologies Office within the Office of Energy Efficiency and Renewable Energy and overseen by ISEN.

According to Dunn, the team will utilize the findings to guide the development of novel chemistries that might lead to more recyclable, bio-based polyurethanes.

"If we want to create a circular economy, other scholars and we will need to keep contributing to this body of information about these supply networks," she added. "We need to comprehend the current state of affairs if we're going to develop cost-effective technologies and generate recycled plastic materials that function as well as or better than what we're used to."

Sustainable Future

Hawkins went on to say that the objective isn't to eliminate plastics but rather to ensure that they are utilized responsibly and sustainably.

"Plastics are helpful and have a lot of societal advantages; if we got rid of plastics, we'd have to deal with all kinds of other issues that would cause environmental harm than the plastics themselves," he added. "As a result, we must continue to search for methods to interfere in the present system and improve things."

For more environmental news, don't forget to follow Nature World News!

© 2025 NatureWorldNews.com All rights reserved. Do not reproduce without permission.