You could decide to hire a 3D printing service in order to get a three dimensional object if you do not have a 3D printer yourself. Sometimes these companies also have CNC services, which is quite different. If you use the 3D printing process in order to produce an item, you will need to design a 3D model beforehand. The 3D printer will need this. Designing the model can be quite hard actually. People often make mistakes when doing this, which could result in bad results. Avoid these mistakes if you are designing a 3D model.

Ignoring material guidelines

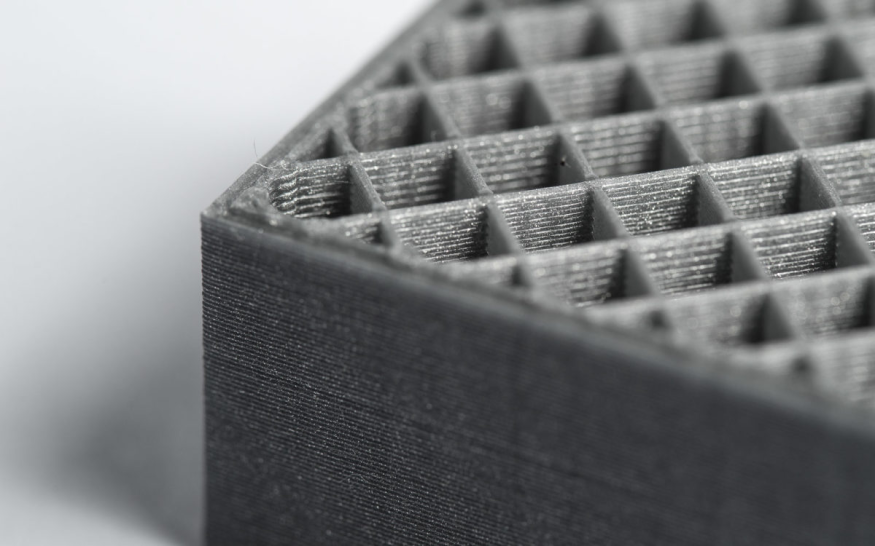

For rapid prototyping you can use a ton of different printing materials. These are all different. Some are strong, while others are brittle. They can be either flexible or solid, rough or smooth, light or heavy, et cetera. In other words, each material that can be used to 3D print an item has its own characteristics. Let's take steel as an example. If your 3D model will be printed in steel there will be particular design recommendations related to the material. You need to use these recommendations in order to design the model the best way.

Ignoring printing technology

The technologies used to 3D print a product are essentially endless. Therefore, it is important to keep in account which printing technology you are going to use, just like with the materials. This can be explained easily by mentioning interlocking parts. You can print interlocking pieces in materials such as ABS and polyamide, but it is not possible if you use gold and silver for example. This is not due to the material itself, instead the reason behind this is the technology used to 3D print these materials. Do not forget to check if your model is possible with the printing technology you want to use.

Ignoring software guidelines

Besides materials and technologies, you also need to take the software guidelines into account. There are many different 3D modeling programs you can use, these are essentially all different in one way or another. Some are mostly used by 3D artists, while others were specifically designed for creating 3D prints. Besides that, they can also differ based on the options they offer to the user. It is thus smart to read the software guidelines before you turn a 3D model into an actual 3D print. Tutorials can help you as well.

Three reasons for architects to use 3D printed models

A 3D printing service can be used for many different applications. You could even hire such a company since you want to use their CNC machining services. However, a lot of people can make use of 3D printing in their day to day life. Besides that, it can also be employed in their work life. Many companies already do this, especially if they need to manufacture products or need to create prototypes. This should also count for architects. The people in this job can use 3D printing to create architectural models, which will have several benefits as you can read down below.

Better visualization

One reason for architects to start using 3D printing in order to create models is about the fact that these models will result in a better visualization for their clients. A 3D printed product will make your design tangible, which is definitely a valuable way to communicate your design concept to your colleagues but especially to your clients. The detailed scale model of the project will show the customer exactly what the building will look like after it has been developed. There will no longer be any guesswork, while the theoretical nature of the drawings and sketches will be taken out of the picture as well.

© 2025 NatureWorldNews.com All rights reserved. Do not reproduce without permission.